Top trends in wooden housewares manufacturing 2023

Top trends in wooden housewares manufacturing 2023

The wooden housewares industry is experiencing a significant shift as manufacturers embrace new technologies, materials, and consumer preferences. This article delves into the top trends impacting the wooden housewares manufacturing sector, highlighting the innovations and strategies that are shaping the future of this dynamic industry. From the rise of e-commerce and sustainable production methods to the increasing demand for customization and the use of advanced technologies, this comprehensive analysis will provide valuable insights for manufacturers, retailers, and consumers alike.

1. The Success of E-commerce in Wooden Housewares

1.1 The Growing Popularity of Online Retail

The housewares industry, like many other sectors, has seen a significant shift towards e-commerce in recent years. Consumers are now more comfortable than ever with purchasing housewares online, leading to an increase in the number of dedicated online stores and marketplaces offering a wide range of wooden housewares products. As a result, manufacturers of wooden housewares have been forced to adapt to this new landscape, developing innovative strategies and platforms to reach their customers in the digital realm.

1.2 The Impact on Wooden Housewares Manufacturers

With e-commerce sales accounting for a growing proportion of the global market, manufacturers of wooden housewares must invest in robust online platforms to showcase their products and engage with customers effectively. This includes not only creating a user-friendly website with comprehensive product listings but also embracing social media, email marketing, and other digital channels to build brand awareness, foster customer loyalty, and drive sales.

2. The Rise in Demand for Sustainable Wooden Housewares

2.1 Consumer Preferences Shifting Towards Eco-Friendly Products

As awareness of environmental issues grows, consumers are increasingly seeking out sustainable products that minimize their impact on the planet. This trend is particularly evident in the wooden housewares industry, where demand for eco-friendly materials and production methods is on the rise. Manufacturers are responding to this shift by developing new product lines using sustainable materials, such as responsibly-sourced wood, recycled elements, and easily biodegradable woods such as bamboo and acacia.

2.2 How Manufacturers of Wooden Housewares Can Adapt

To meet the growing demand for sustainable wooden housewares, manufacturers must invest in research and development to identify new materials and production techniques that align with eco-friendly principles. This could include partnering with certifying organizations, such as the Forest Stewardship Council (FSC), to ensure the responsible sourcing of materials or exploring innovative manufacturing processes that minimize waste and reduce the overall environmental footprint of their products.

3. The Increased Role of Social Media in Wooden Housewares Shopping

3.1 The Emergence of Social Shopping Platforms

Social media platforms are playing an increasingly important role in the wooden housewares shopping experience, offering consumers new ways to discover, research, and purchase products. Platforms like Instagram, Facebook, and Pinterest have evolved to incorporate e-commerce features, enabling users to buy products directly from their feeds, while influencers wield significant power in shaping consumer preferences and driving sales.

3.2 The Implications for Manufacturers of Wooden Housewares

For manufacturers of wooden housewares, the rise of social shopping presents both challenges and opportunities. To capitalize on this trend, manufacturers must develop a robust social media strategy, including high-quality content, targeted advertising, and partnerships with key influencers in the sector. By engaging with customers on social media platforms, manufacturers can build brand awareness, drive traffic to their online stores, and ultimately, boost sales.

4. The Use of Advanced Technologies in Wooden Housewares Manufacturing

4.1 The Adoption of Computer-Aided Design (CAD) and 3D Printing

Advancements in technology are revolutionizing the wooden housewares manufacturing process, enabling manufacturers to create more intricate designs, streamline production, and reduce costs. Computer-aided design (CAD) software and 3D printing technologies are at the forefront of this transformation, allowing manufacturers to create detailed digital models of their products and produce prototypes rapidly.

4.2 How Manufacturers of Wooden Housewares Can Benefit

By embracing advanced technologies like CAD and 3D printing, manufacturers of wooden housewares can optimize their design and production processes, resulting in more innovative products, faster time-to-market, and increased efficiency. Additionally, these technologies can facilitate greater customization, enabling manufacturers to offer a wider range of bespoke wooden housewares to meet the diverse needs and preferences of their customers.

5. Changing Lifestyles and Its Demands on Wooden Housewares

5.1 The Shift Towards Smaller Living Spaces and Multifunctional Furniture

As urbanization continues to increase and living spaces become smaller, consumers are demanding more versatile and space-saving wooden housewares. This trend is driving manufacturers to develop innovative products that can serve multiple functions, such as modular furniture systems, collapsible or stackable designs, and housewares with built-in storage solutions.

5.2 How Manufacturers of Wooden Housewares Can Respond

To cater to the changing needs of consumers, manufacturers of wooden housewares must invest in research and development to create products that are not only stylish and high-quality but also functional and space-efficient. By offering a diverse range of adaptable and multifunctional wooden housewares, manufacturers can appeal to a broader audience and differentiate themselves in an increasingly competitive market.

6. Changing Demography of the Workforce in Wooden Housewares Manufacturing

6.1 The Shift Towards a Younger, More Diverse Workforce

As the demographics of the workforce in the wooden housewares manufacturing sector evolve, manufacturers must adapt their recruitment and retention strategies to attract and retain talent from a diverse range of backgrounds. This includes recognizing and addressing the unique needs and priorities of younger workers, such as offering flexible work arrangements, opportunities for professional development, and a supportive work environment.

6.2 Strategies for Manufacturers of Wooden Housewares

To attract and retain a diverse workforce, manufacturers of wooden housewares must invest in targeted recruitment initiatives, comprehensive training programs, and inclusive workplace policies. By fostering a culture of diversity and inclusion, manufacturers can ensure they have access to the full range of skills, perspectives, and experience needed to drive innovation and growth in the industry.

7. Reducing the Skills Gap in the Wooden Housewares Manufacturing Industry

7.1 The Challenge of an Evolving Workforce

The wooden housewares manufacturing industry faces a significant skills gap as older workers retire and younger workers enter the workforce with different skill sets and educational backgrounds. This gap presents a major challenge for manufacturers, who must find ways to bridge the divide between the technical expertise of older workers and the digital skills of their younger counterparts.

7.2 Strategies for Manufacturers of Wooden Housewares

To address the skills gap in the wooden housewares manufacturing industry, manufacturers must invest in comprehensive training programs, mentorship initiatives, and partnerships with educational institutions. By providing workers with the necessary skills, resources, and support, manufacturers can ensure a seamless transition between generations and maintain a skilled workforce capable of driving the industry forward.

8. Manufacturing-as-a-Service (MaaS) in the Wooden Housewares Industry

8.1 The Shift Towards Direct-to-Consumer Sales

As the traditional B2B model gives way to a more customer-centric approach, manufacturers of wooden housewares are increasingly exploring the potential of Manufacturing-as-a-Service (MaaS). This model allows manufacturers to sell their products directly to consumers, eliminating the need for intermediaries and enabling them to offer more competitive pricing and a greater degree of customization.

8.2 The Benefits of MaaS for Manufacturers of Wooden Housewares

By adopting a MaaS model, manufacturers of wooden housewares can gain greater control over their supply chains, reduce costs, and enhance customer relationships. Additionally, this approach allows manufacturers to gather valuable data on consumer preferences and trends, enabling them to make more informed decisions about product development, marketing, and sales strategies.

9. The Rise of Machine Learning and Robotics in Wooden Housewares Manufacturing

9.1 The Integration of Advanced Technologies in Production Processes

Machine learning and robotics are playing an increasingly important role in the wooden housewares manufacturing industry, enabling manufacturers to automate complex tasks, streamline operations, and improve efficiency. From computer-controlled cutting and shaping tools to automated assembly lines, these advanced technologies are transforming the way wooden housewares are designed and produced.

9.2 The Implications for Manufacturers of Wooden Housewares

To stay competitive in the rapidly evolving wooden housewares industry, manufacturers must invest in advanced technologies and integrate them into their production processes. By embracing automation, machine learning, and robotics, manufacturers can increase productivity, reduce costs, and maintain a high level of quality and precision in their products.

10. The Rise in the Need for Customized Wooden Housewares

10.1 The Growing Demand for Personalized Products

In today's consumer-driven market, customization is becoming increasingly important, with customers seeking unique and personalized wooden housewares that reflect their individual tastes and preferences. This trend is driving manufacturers to offer a greater range of customization options, from bespoke designs and finishes to tailored sizes and configurations.

10.2 How Manufacturers of Wooden Housewares Can Meet This Demand

To cater to the growing demand for customized wooden housewares, manufacturers must invest in advanced technologies and flexible production processes that allow for greater personalization and customization. This could include offering online design tools, implementing modular production systems, or partnering with specialized suppliers to provide a wider range of materials and finishes. By embracing customization, manufacturers can differentiate themselves in a crowded market and foster customer loyalty, ultimately driving long-term growth and success.

Learn more about 10 essential tips for collaborating with Vietnamese Wooden Products Manufacturers

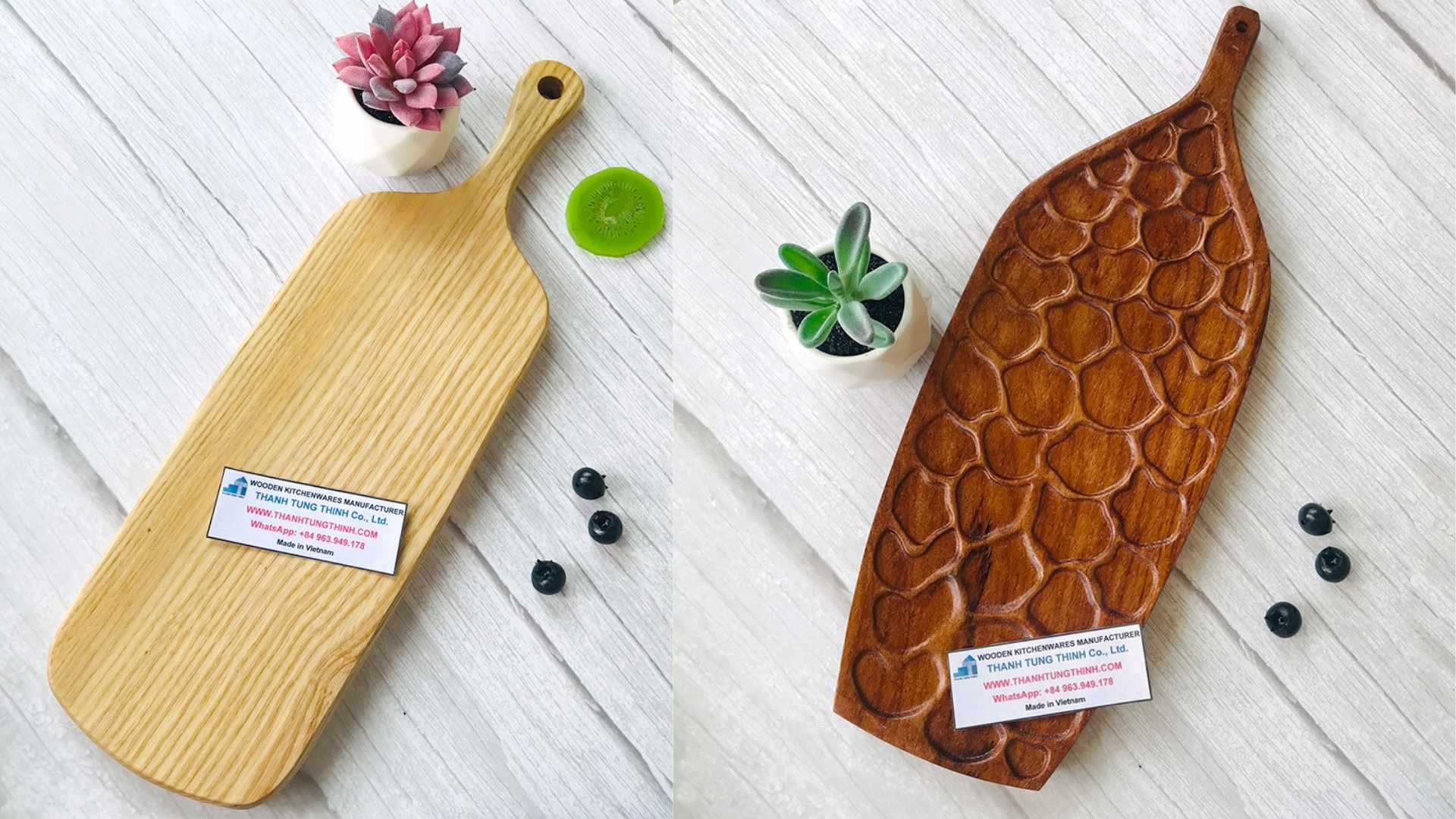

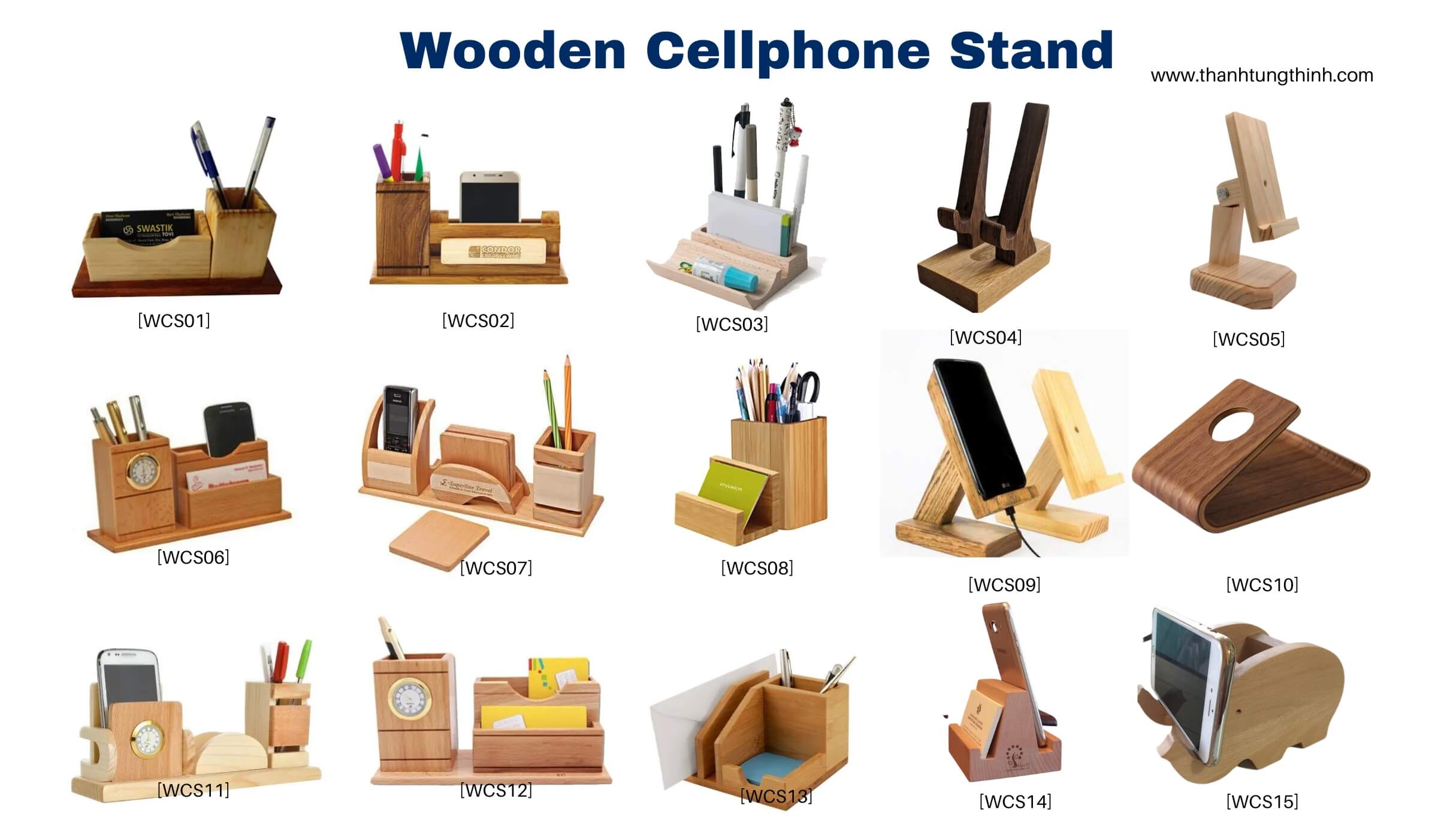

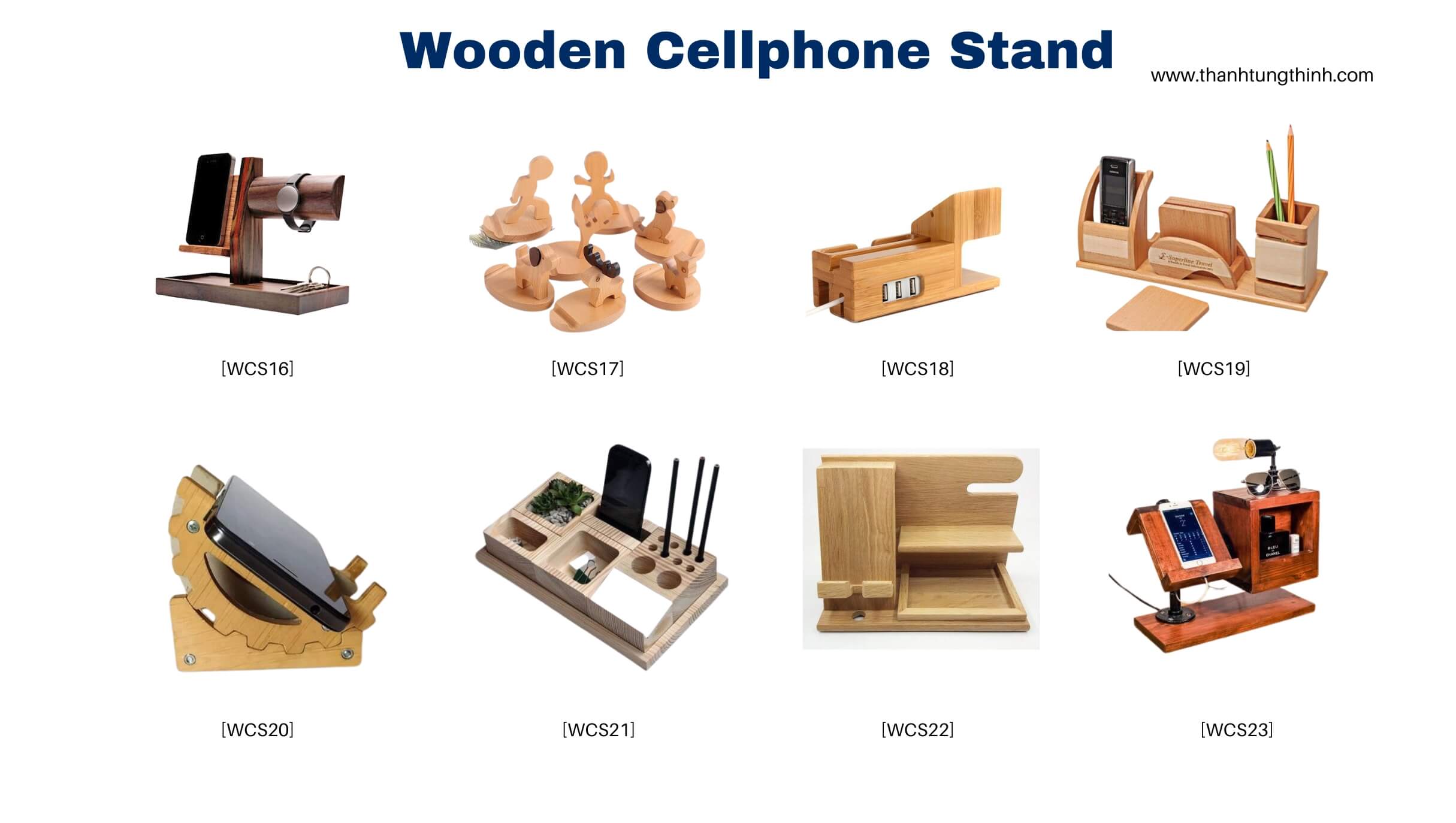

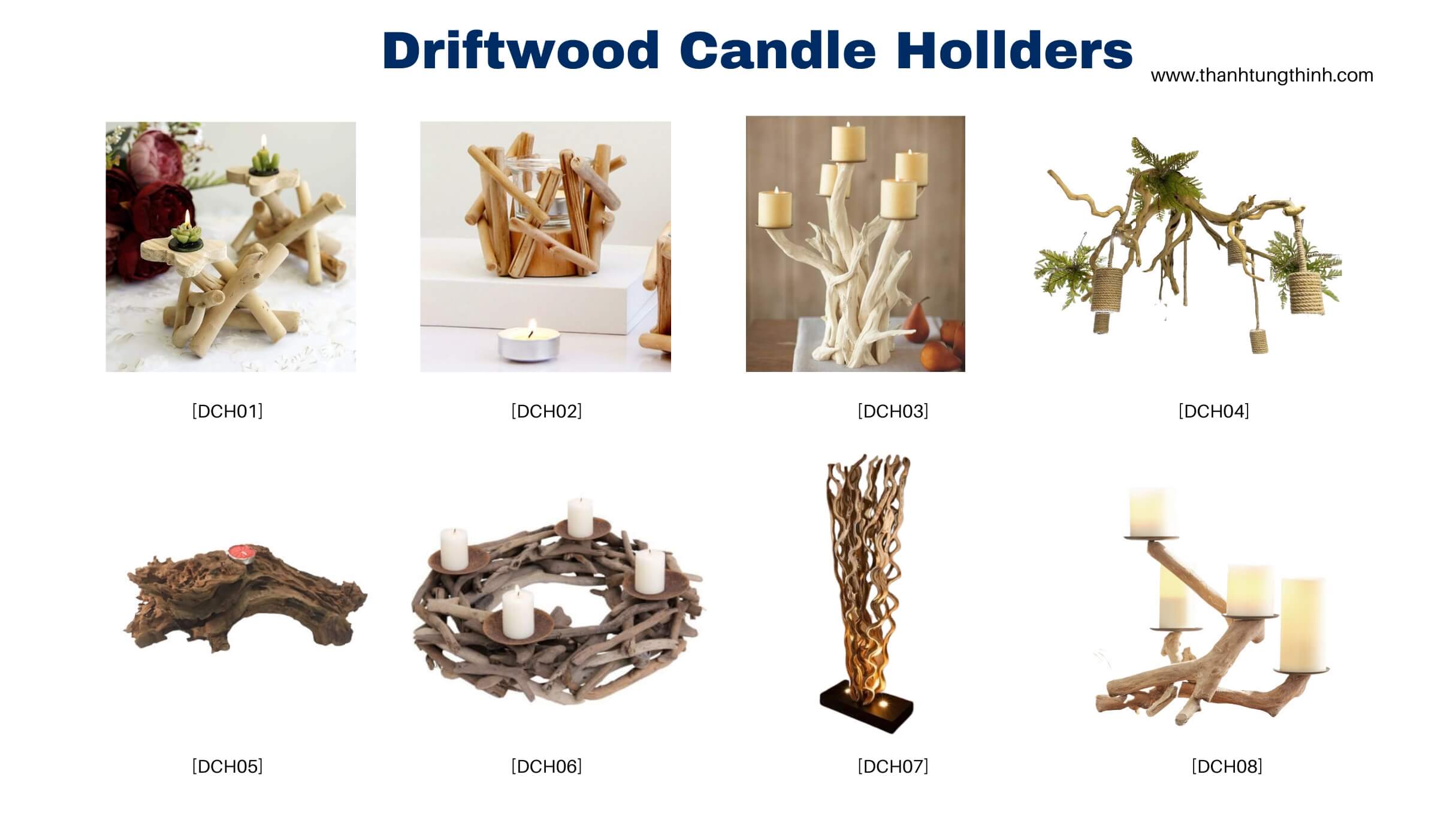

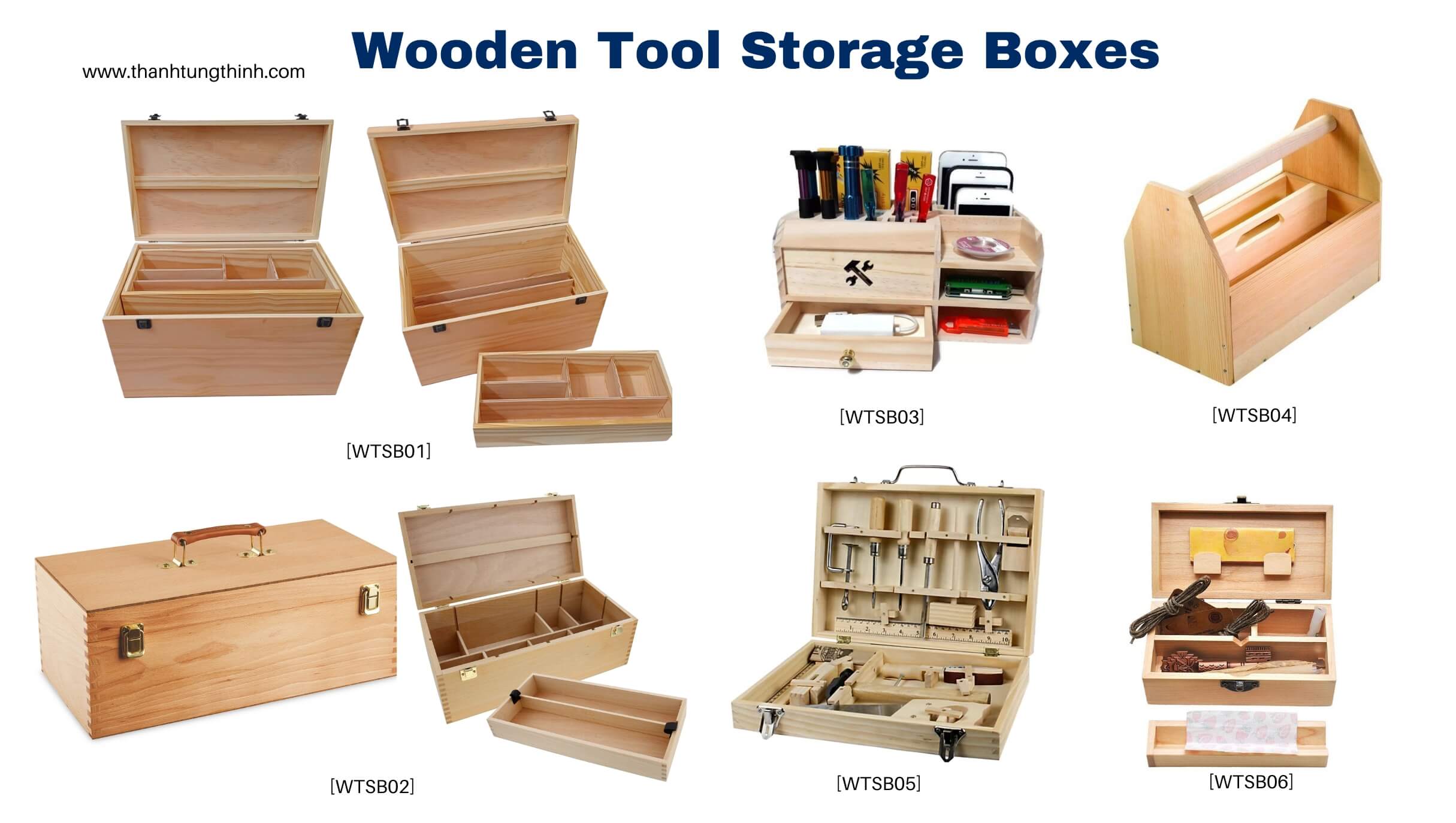

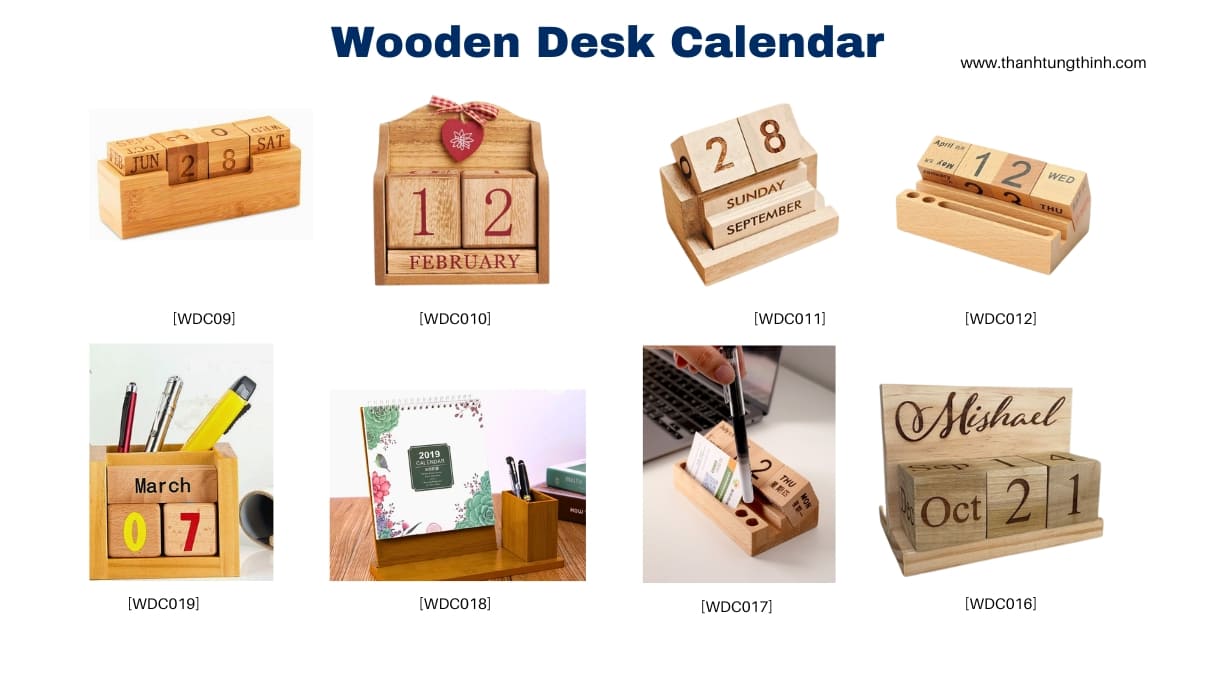

11. Thanh Tung Thinh Co., LTD specializes in manufacturing and exporting high-quality housewares

If you are looking to capture market trends to grow your business related to wooden housewares, then we are a great partner for you.We are confident to bring you a source of the best quality, guaranteed in terms of price as well as the necessary standards to sell in your country's market. Our wood products have been exported to 45 countries around the world, including major countries such as the US, UK, Australia, Germany, Japan, Korea, Singapore,...

Thanh Tung Thinh Co,. LD owns 2 factories in the key area for producing wooden housewares. With skilled workers, and a highly qualified management team, our wooden products always satisfy our partners and bring them a huge profit in business.

Moreover, we also focus on investing in machinery and technology, so we can always meet the production of wooden housewares in large quantities or at the request of customers. Our policies and support services always help customers import goods in the most convenient and cost-effective way possible.

Therefore, do not hesitate to contact us immediately if you are in need of this wooden houseware business!

In conclusion, the wooden housewares manufacturing industry is undergoing significant changes, driven by shifting consumer preferences, technological advancements, and evolving market dynamics. By staying informed about these trends and adapting their strategies accordingly, manufacturers of wooden housewares can position themselves for success in a rapidly changing marketplace.